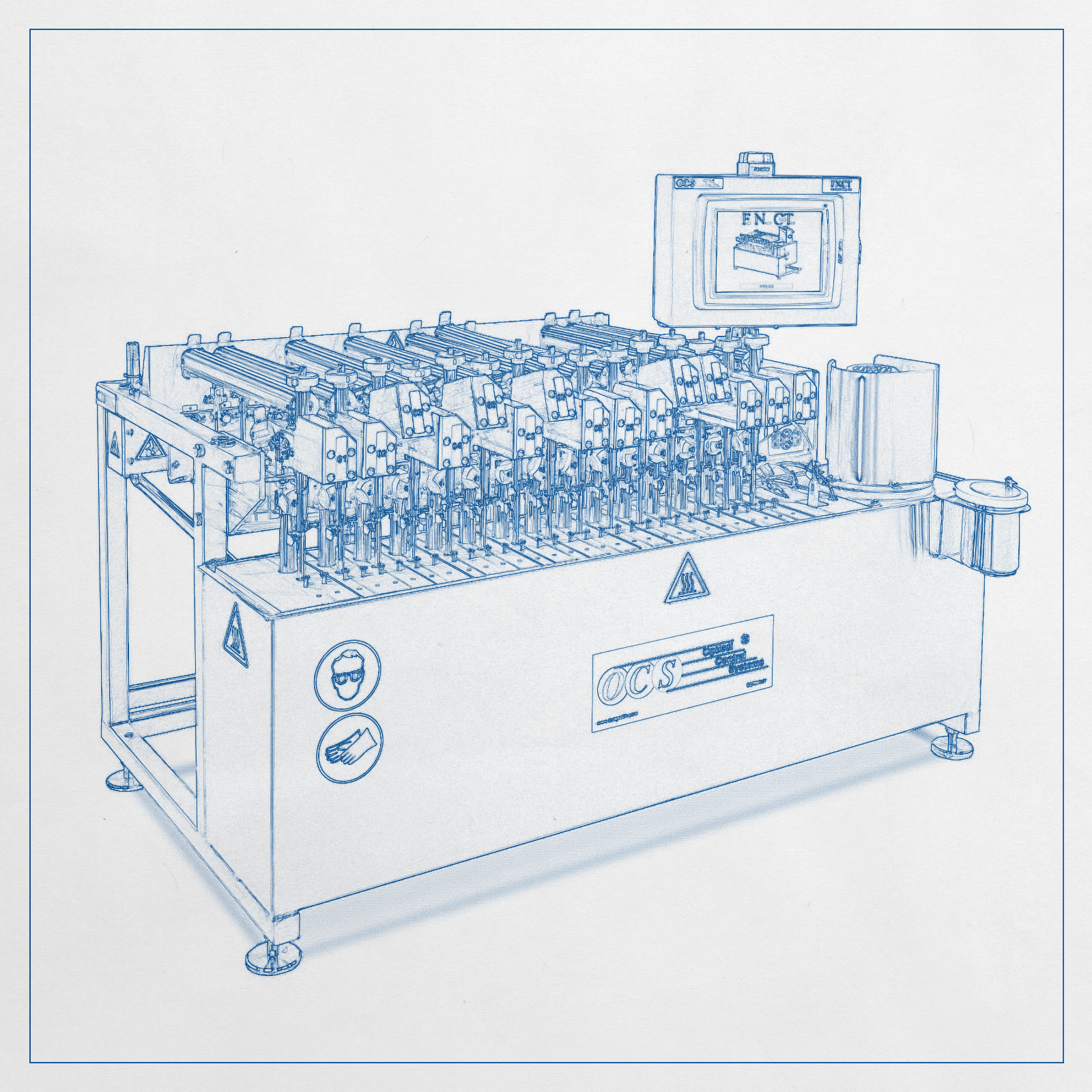

Full Notch Creep Test (FNCT)

The OCS Full Notch Creep Test (FNCT) is a widely used method of classifying polyethylene materials in terms of their slow crack growth behaviour under accelerated conditions. A circumferentially notched body is loaded in a tempered wetting agent with a defined tensile stress, and the time until a break occurs is measured.

Testable Raw Materials

- Polyethylene materials

Features

- 15 sample stations with independent tensile stress adjustment and data acquisition

- Load application through easily adjustable lever weight system

- Precise adjustment of tensile stress through electronic force sensor

- Uniform bath temperature control through extensive bath insulation

- Exhaust air connections for targeted vapour extraction

- Continuous pH value measurement with adjustable warning and alarm thresholds

- No time limit on test times, time resolution: 1 second (real time)

- Operation via touch panel with data trend as well as optical and acoustic alarm functions

- High chemical resistance of the material used (stainless steel)

- Developed according to ISO 16770

Sales Team

T +49 2302 95622-0

F +49 2302 95622-33

info@ocsgmbh.com

www.ocsgmbh.com

Address

OCS Optical Control Systems GmbH

Wullener Feld 24

58454 Witten

Germany